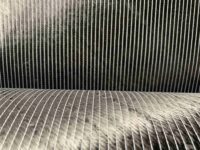

Advantages of using multiaxial Carbon fabric

- Because the fibres are always straight and non-crimped and also the fact that several orientations(0°, 45°, 90°) of fibres are possible on one fabric, these multiaxial fabrics are able to offer the maximum mechanical strength.

- Since Multiaxial fabrics are thicker and with multiple fibre orientations, fewer layers are needed to build a laminate. This results in a faster building speed and saving labor costs as well.

| Product No. | Material | Stitching type & fiber orientation | Fabric Weight (g/m2) | 0°Layer | +45°Layer | +90°Layer | -45°Layer(g/m2) | Polyester Yarn | Standard Width |

| Type | (g/m2) | (g/m2) | (g/m2) | (g/m2) | (m) | ||||

| CATX300-A | Carbon 12K/24K | Triaxial +45°/ -45°/ 0° | 306 | 100 | 100 | 100 | / | 6 | 1.27 |

| CATX300-B | Carbon 12K/24K | Triaxial 90°/ 0°/ 90° | 306 | 100 | / | 200 | / | 6 | 1.27 |

1.27 meter in width; Each roll is 50/100 meters.

Fiber brands can be Toray, Formosa, Dowaksa, Mitsubishi depending on your requirement.