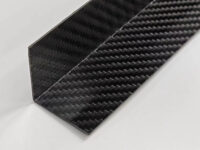

G-10 is very similar to carbon fiber laminates, except the base material used is E- glass cloth. G-10 is the toughest of the glass fiber resin laminates and therefore the most commonly used.

- Available thickness range: 0.2mm to 50mm

- Available maximum size: 1020mm X 1220mm

- Maximum temperature resistance: 130 C

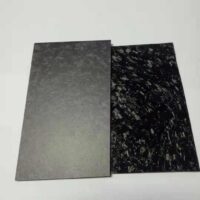

- Available colors: green, black, white, yellow

Properties

G-10 is favored for its high strength, low moisture absorption, and high level of electrical insulation and chemical resistance. These properties are maintained not only at room temperature but also under humid or moist conditions.

G-10 was first used as a substrate for printed circuit boards, and its designation, G-10, comes from a National Electrical Manufacturers Association standard for this purpose.

Decorative variations of G-10 are produced in many colors and patterns and are especially used to make handles for knives, grips for firearms and other tools. These can be textured (for grip), bead blasted, sanded or polished. Its strength and low density make it useful for other kinds of handcrafting as well.

We also supply a flame retarded (also known as FR-4 version of these G10 laminates)

We also provide CNC service on these sheets.

Here’s the link to more technical data TDS-G10 laminates.