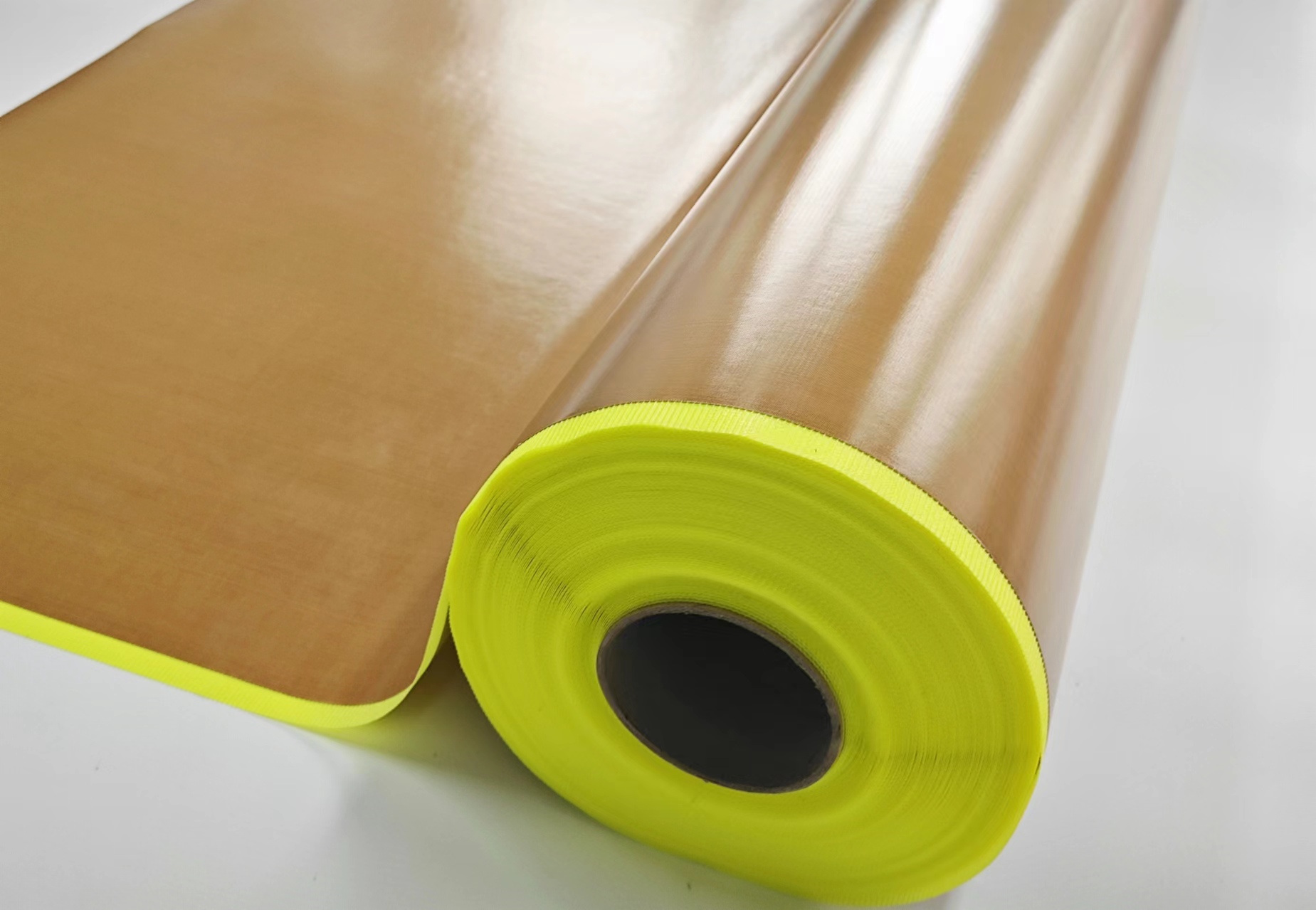

Advantages of using PTFE Coated fiberglass fabric

• PTFE-coated fiberglass with silicone adhesive provides permanent release saving time spent cleaning tooling and reapplying release agents.

• It can be used to recondition worn or damaged tools for extended service, avoiding the cost of remanufacturing.

• It improves tooling surface finish and aid resin flow for better part surface finish and reduced hand finishing.

Physical Properties

| Carrier | fiberglass fabric with PTFE coating |

| Adhesive type | Silicone |

| Colour | Brown |

| Total thickness | 175 μm (0.007”) |

| Film thickness | 125 μm (0.005”) |

| Adhesive thickness | 50μm(0.002”) |

| Shelf life | 18 months at RT |

|

Maximum use temperature Carrier type

|

260°C

|

Standard Roll Size

1m wide X 50/100 m long

1.2m wide X50/100 m long

Other sizes can also be made available.