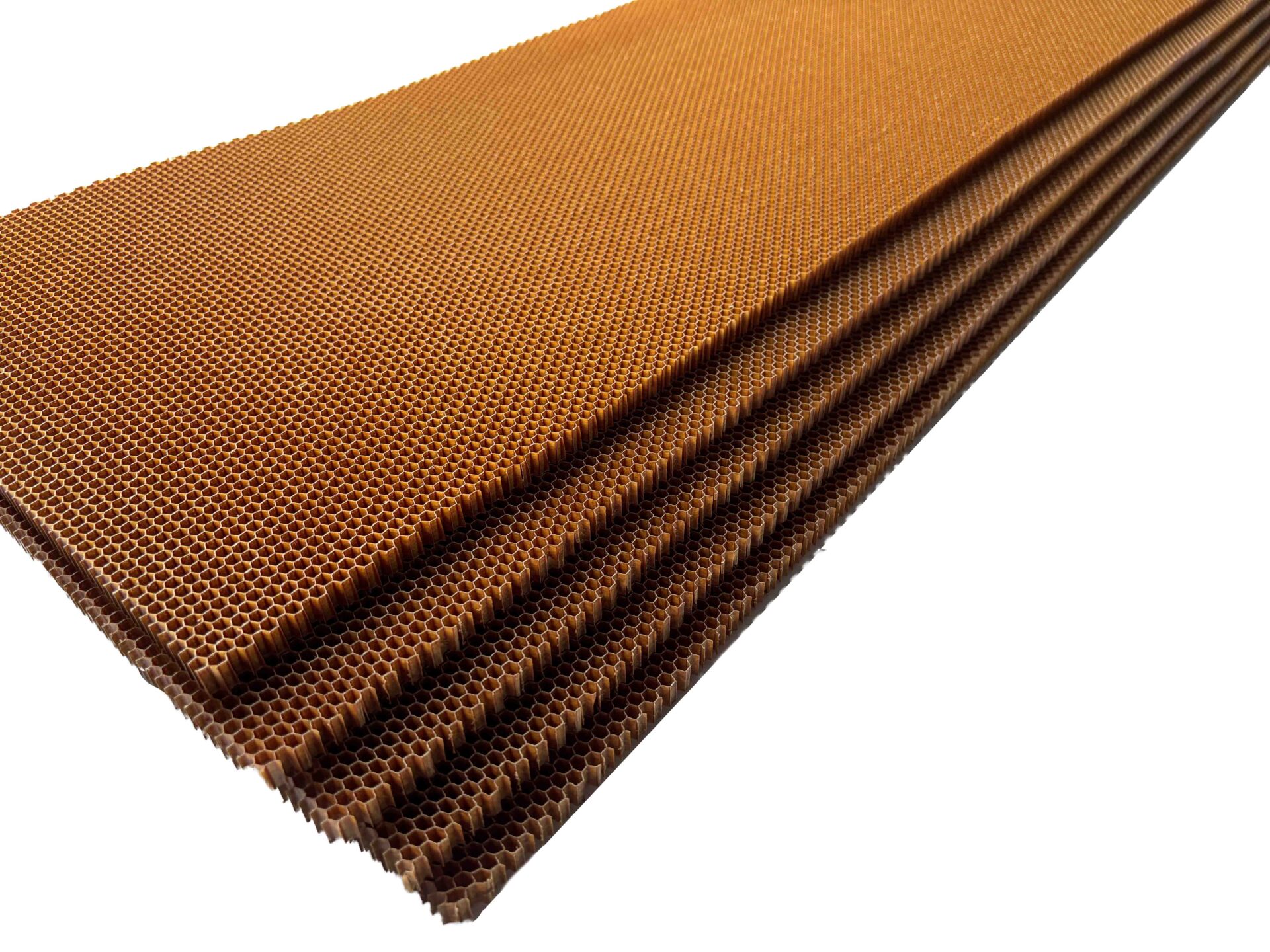

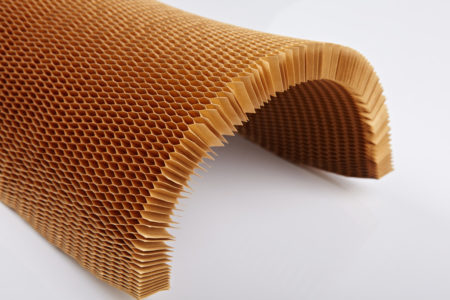

Key Features of Nomex Honeycomb Cores

- High Strength to Weight Ratio

- Easy and flexible to process

- Corrosion Resistant

- Flame Retarded

- Good Thermal Insulation

- Thickness starts at 2.5mm

- Two kinds of cell configuration available: REGULAR HEX(RH) and Over expanded(OX)

Typical Properties of Nomex Honeycomb core

|

Cell Size |

in mm in inches |

3.2, 4.0, 4.8, 6.4, 8.0, 9.5 1/8, 5/32, 3/16, 1/4, 5/16, 3/8 |

|

Density |

in Kg/m3 in b/ft3 |

24, 29, 40, 48, 64, 80, 96, 128 1.5, 1.8, 2.5, 3.0, 4.0, 5.0, 6.0, 8.0 |

|

Size |

in mm |

1200×2500, 1300×2600; Can be cut into custom size |

Applications

✅ Aerospace – Aircraft interiors, engine nacelles, fairings, radomes, and satellite structures.

✅ Automotive – Lightweight body panels, racing car components, and energy absorption structures.

✅ Marine – Bulkheads, decks, hull reinforcements, and interior panels.

✅ Rail & Transportation – Train floors, walls, ceilings, and lightweight structural panels.

✅ Defense & Ballistics – Blast-resistant structures, body armor, and military vehicle components.

✅ Industrial & Sporting Goods – Wind turbine blades, electronics enclosures, skis, and performance gear.

We supply two grades of Nomex honeycomb core, below are links to their technical data sheets.