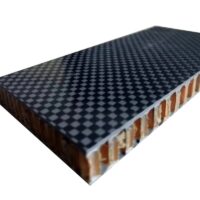

Key Features of Kevlar Honeycomb Core

- Manufactured by the impregnation para-aramid(kevlar) papers with heat resistant phenolic resin.

- Mechanical Strength is stronger than Nomex by about 40%

- Improved resistance to fatigue and abrasion

- Improved Corrosion Resistant

- Good insulator of electricity and heat

- Flame Retarded

- Thickness starts at 2.5mm

- Two kinds of cell configuration available: REGULAR HEX(RH) and Over expanded(OX)

Key Specifications of our Kevlar Honeycomb Cores

|

Cell Size |

in mm

in inches |

3.2, 4.0, 4.8

1/8, 5/32, 3/16 |

|

Density |

in Kg/m3

in b/ft3 |

40, 48 , 64, 80, 96, 128

2.5, 3.0, 4.0 , 5.0, 6.0, 8.0 |

|

Sheet Size |

in mm

in Inches |

1220×2440 1300×2600 1600×3200

48×96” 51×102” 63×126” |

As you can see in the above table, we are able to supply kevlar honeycomb cores in various densities and cell size. Standard sheet size is 50×100 inches which can be customized according to your needs.

We also build sandwich panels using these Kevlar honeycomb cores and carbon/kevlar/glass fiber skins.

Applications of Kevlar Honeycomb Core

- Boat Hulls, Ship panels

- Racing cars, trains,

- Military equipments like tanks, drones, guns etc.

- Aircraft galleys, Quadcopters etc.