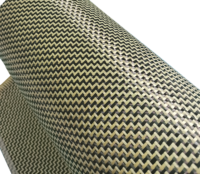

list of Kevlar fabrics

| Weight GSM |

Fiber Type | Weave | warp | weft | thickness in mm |

| 50 | 200D | Plain | 13.5 | 13.5 | 0.08 |

| 80 | 400D | Plain | 12 | 12 | 0.14 |

| 100 | 600D | Plain | 8 | 8 | 0.15 |

| 115 | 800D | Plain | 7 | 7 | 0.16 |

| 140 | 1000D | Plain | 6 | 6 | 0.22 |

| 160 | 1000D | Plain | 7 | 7 | 0.24 |

| 160 | 1000D | twill | 7 | 7 | 0.24 |

| 200 | 1000D | plain | 9 | 9 | 0.26 |

| 200 | 1000D | twill | 9 | 9 | 0.26 |

| 170 | 1500D | plain | 5 | 5 | 0.23 |

| 200 | 1500D | plain | 6 | 6 | 0.26 |

| 220 | 1500D | twill | 6.5 | 6.5 | 0.28 |

| 300 | 3000D | plain | 4.5 | 4.5 | 0.4 |

| 450 | 3000D | plain | 6 | 6 | 0.6 |

Why use Aramid fibers?

- High strength

- Good resistance to abrasion

- Good resistance to organic solvents

- Non-conductive

- No melting point

- Low flammability

- Good fabric integrity at elevated temperatures

Main applications

- Bullet proof vests

- Aircrafts

- Sporting goods

- Conveyer belt

- High strength ropes

- Building reinforcements

- Heat and flame resistant garments