Properties of the resin system

• Curing temperature: 100-150 °C

• Gel time: 20-23 minutes at 130 °C

• 9-11 minutes at 140 °C

• 5-7 minutes at 150 °C

• Glass transition (Tg) : 120~130℃ (after curing at 140 C for 120 minutes or 60 minutes at 150 C)

• Suitable for applications requiring UL-94V0 compliance

We have carbon fiber, fiberglass and Kevlar prepregs made from this flame-retardant epoxy resin.

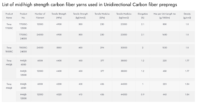

List of Flame retardant Epoxy resin Carbon fiber prepregs

| Model N0. | Fiber type | Aerial weight GSM |

Resin content % |

Thickness mm |

Roll width | Roll length |

| FRE-CFP-UD-12k-150 | 12k | 150 | 40 | 0.15 | 1 meter | 50-100 meters |

| FRE-CFP-PL -3k-200 | 3k | 200 | 45 | 0.2 | 1 meter | 50-100 meters |

| FR-CFP-TW-3k-200 | 3k | 200 | 45 | 0.2 | 1 meter | 50-100 meters |

List of Flame retardant Epoxy resin Kevlar prepregs

| Model N0. | Fiber Type | Aerial weight GSM |

Resin content % |

Thickness mm |

Roll width | Roll length |

| FRE-KFP-PL-1500D-200 | 1500D | 200 gsm | 40% | 0.20mm | 1 meter | 50-100 meters |

| FRE-KFP-PL-3000D-300 | 3000D | 300 gsm | 40% | 0.35mm | 1 meter | 50-100 meters |

List of Flame retardant Epoxy resin fiberglass prepregs

| Model N0. | Fiber type | Aerial weight GSM |

Resin content % |

Thickness mm |

Roll width | Roll length |

| FRE-GFP-PL-200 | E-glass 1200 Tex | 200 | 35 | 0.15 | 1 meter | 50-100 meters |

| FRE-GFP-PL-400 | E-glass 2400 Tex | 400 | 35 | 0.35 | 1 meter | 50-100 meters |

Transportation and Storage

These flame retarded prepregs do not require any special refrigerated packaging and transportation. They can be stored for about a month at room temperature (25 °C ) and for an year in freezer( -18 °C)