We specialize in high-performance compression molded parts, engineered for superior strength, precision, and durability. Our advanced compression molding process allows us to produce complex, high-strength composite components that meet the demanding requirements of various industries, including aerospace, automotive, marine, industrial, and medical applications.

Applications of Our Compression Molded Parts

🔹 Aerospace & Defense – Lightweight and high-strength components for aircraft and defense systems.

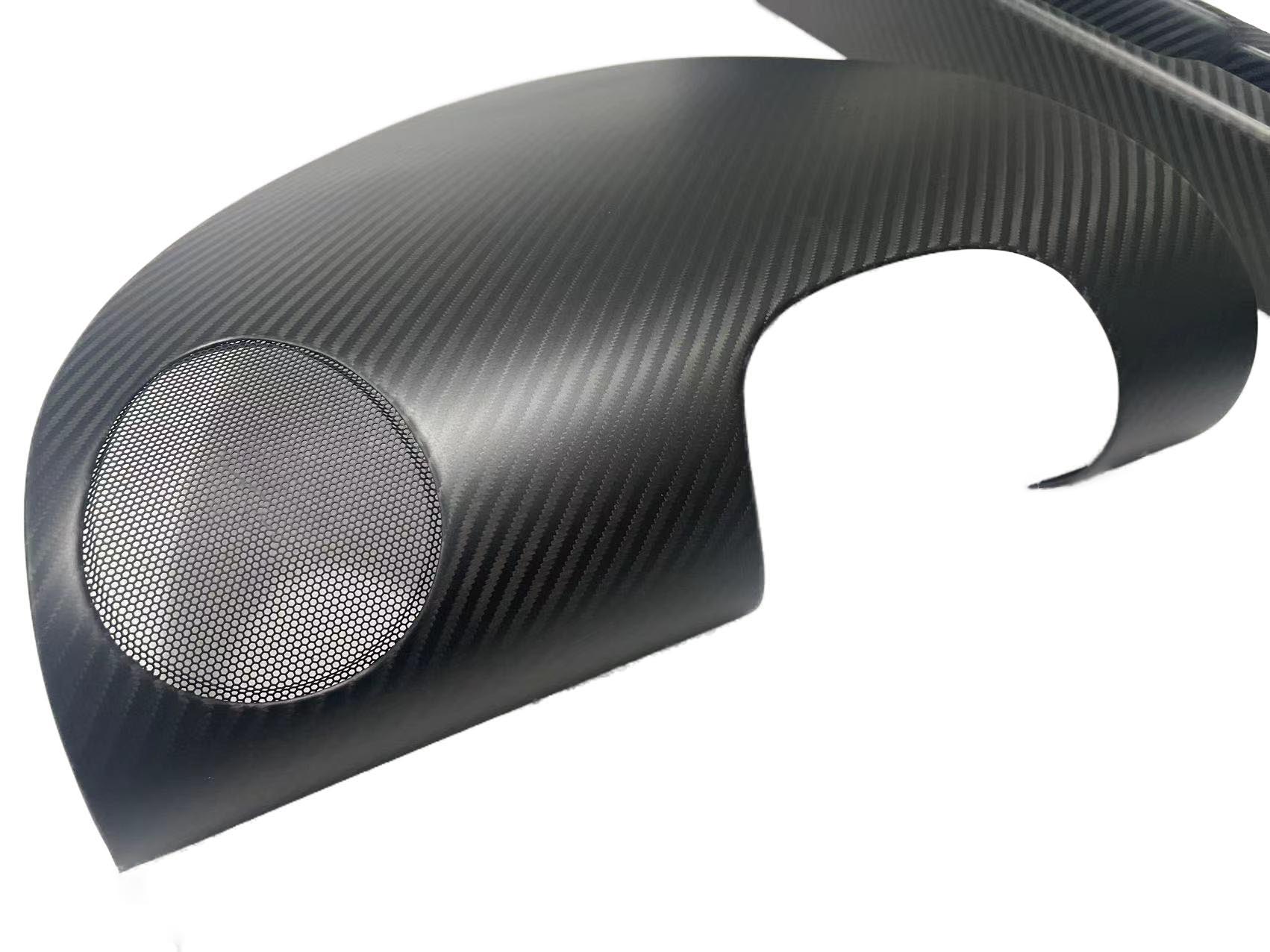

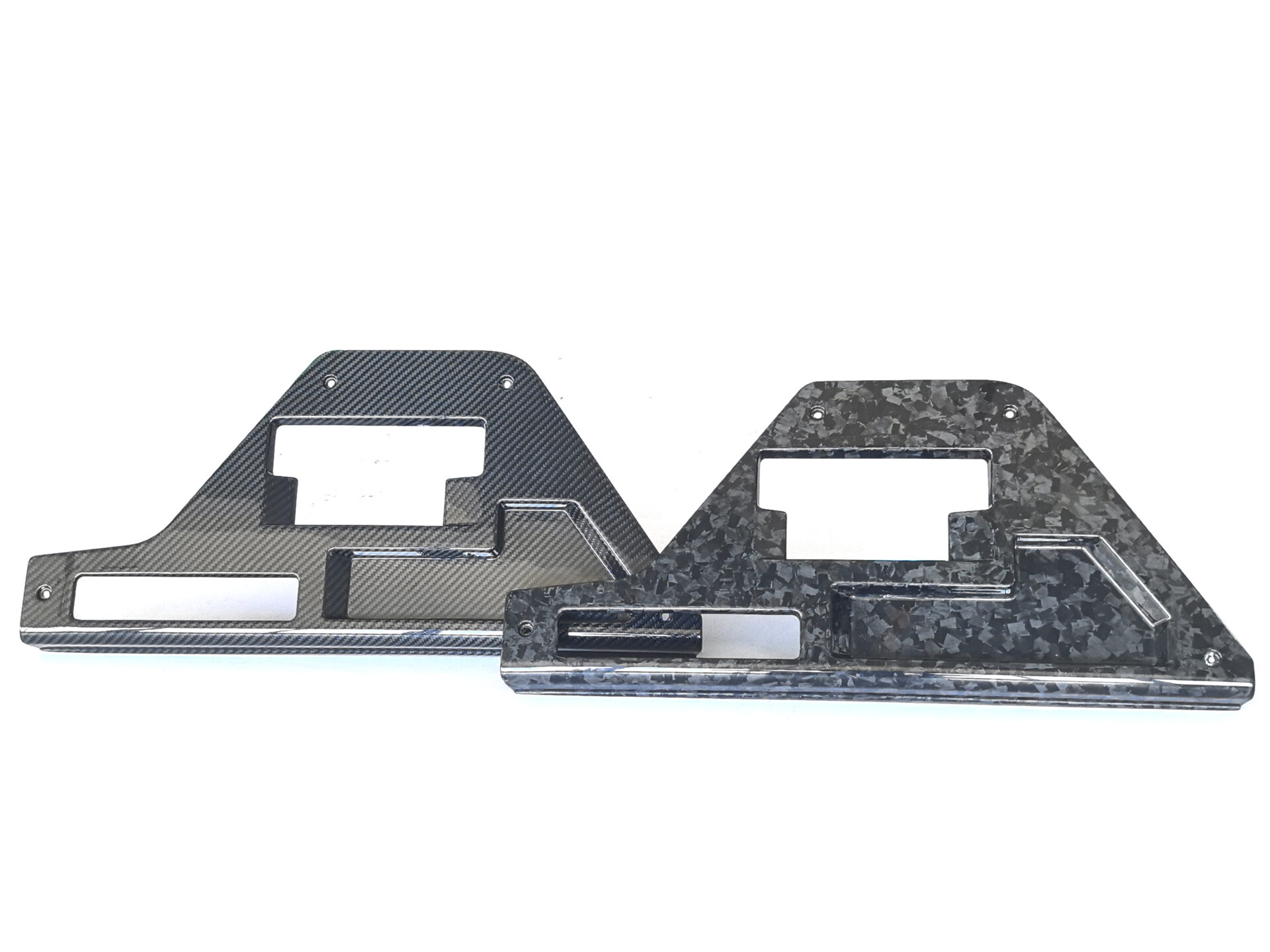

🔹 Automotive & Motorsport – Impact-resistant parts for high-performance vehicles.

🔹 Industrial Equipment – Durable structural parts for heavy-duty machinery.

🔹 Medical Devices – Precision-molded parts for healthcare applications.

Our Capabilities

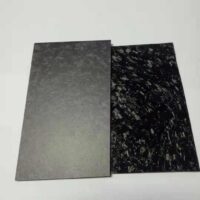

✔ Custom Material Selection – We work with carbon fiber, fiberglass, Kevlar®, and other advanced composites.

✔ Tailored to Your Needs – We manufacture customized parts based on your specifications.

✔ Strict Quality Control – Ensuring consistency and compliance with industry standards.