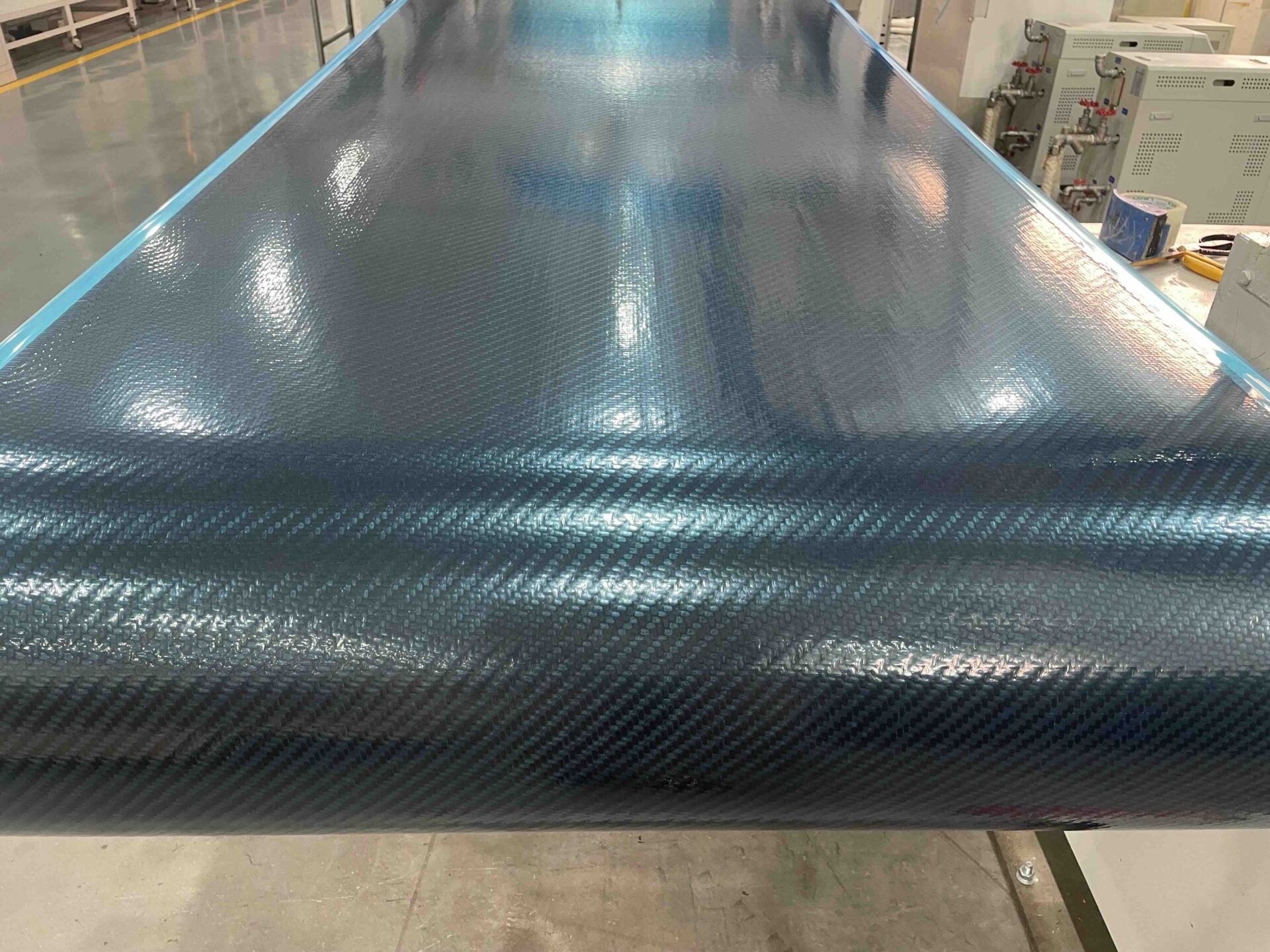

12k 400 GSM Carbon fiber prepreg

|

Resin type |

TNYPH-42T |

| Minimum cure temperature | 115 ℃ |

| TG start | 135℃ |

| TG peak | 145℃ |

| Fibre | Zhongfu SYT49 |

| Reinforcement type | Twill (and plain) |

| fiber count/cm | warp:2.5 |

| weft:2.5 | |

| Cure time/temperature | 90℃*120min+100℃*100min-120min; Can be adjusted accordingly |

| Fiber weight (g/㎡) | 400±5% |

| Prepreg weight (g/㎡) | 666±5 |

| Prepreg resin content (%) | 40±3 |

| Out-life at 20℃ | 25 Days |

| Storage life at 0℃ | 4 months |

Methods of Curing

Our Prepregs are extremely convenient to work with and can be processed in a variety of methods:

- Autoclave

- Out of Autoclave

- Heat-press moulding

- Heat-shrink wrapped

Ideal curing process for our prepregs

- Once you take out the prepreg from the freezer, let it defrost overnight.

- For curing, first, cure it at about 80C for about 30 minutes

- Then raise to 120C, for 120 minutes.. If 130 C, only 60 minutes. About 4 hours if at 100 C

- Wait until the temperature lowers to 60 C , then remove the mould

This is the process for our default/standard resin system, we also supply prepregs made using other epoxy resin systems with different Tg and curing temperatures.

Storage and Transportation

Our Prepregs can be stored at room temperature for about a month hence do not require freezer bags for transportation. But if stored in a freezer (at about -18°C) then our prepreg can last for more than 6 months.

Options on resin systems for Prepregs

List of Resin systems used in prepregs supplied by CA Composites |

|||

| Resin Name | Glass Transition (Tg) | Curing Condition | Remarks |

| TNYPH-23 | 100-110 | 120 minutes at 90 C + 120 minutes at 100 C | standard resin/slightly lower curing temp |

| TNYPH-42 | 120-130 | 30 minutes at 80 C + 100-120 minutes at 120-125C | Standard tg/standard curing temp |

| JS-YPH170 | 175-180 | 30 minutes at 80 C + 90 minutes at 150 C | moderately high tg |

| TN-YPH170 | 170-190 | 30 minutes at 80 C + 45 minutes at 160 C | moderately high tg |

| JS-YPH200 | 195-205 | 30 minutes at 150 C + 120 minutes at 200 C (after cure) | highest Tg |

| TN-FR-Epoxy | 120-130 | 30 minutes at 80 C + 30 minutes at 150 C (or 90 minutes at 120 C) | Flame Retardant/ UL94 V-0 compliant |

| JS-FR-Epoxy | 120-130 | 30 minutes at 80 C + 90 minutes at 120 C | Flame Retardant/ UL94 V-0 compliant |

| JS-YPH150 | 140-150 | 5-10 minutes at 150 C | Superfast curing and moderately high tg |