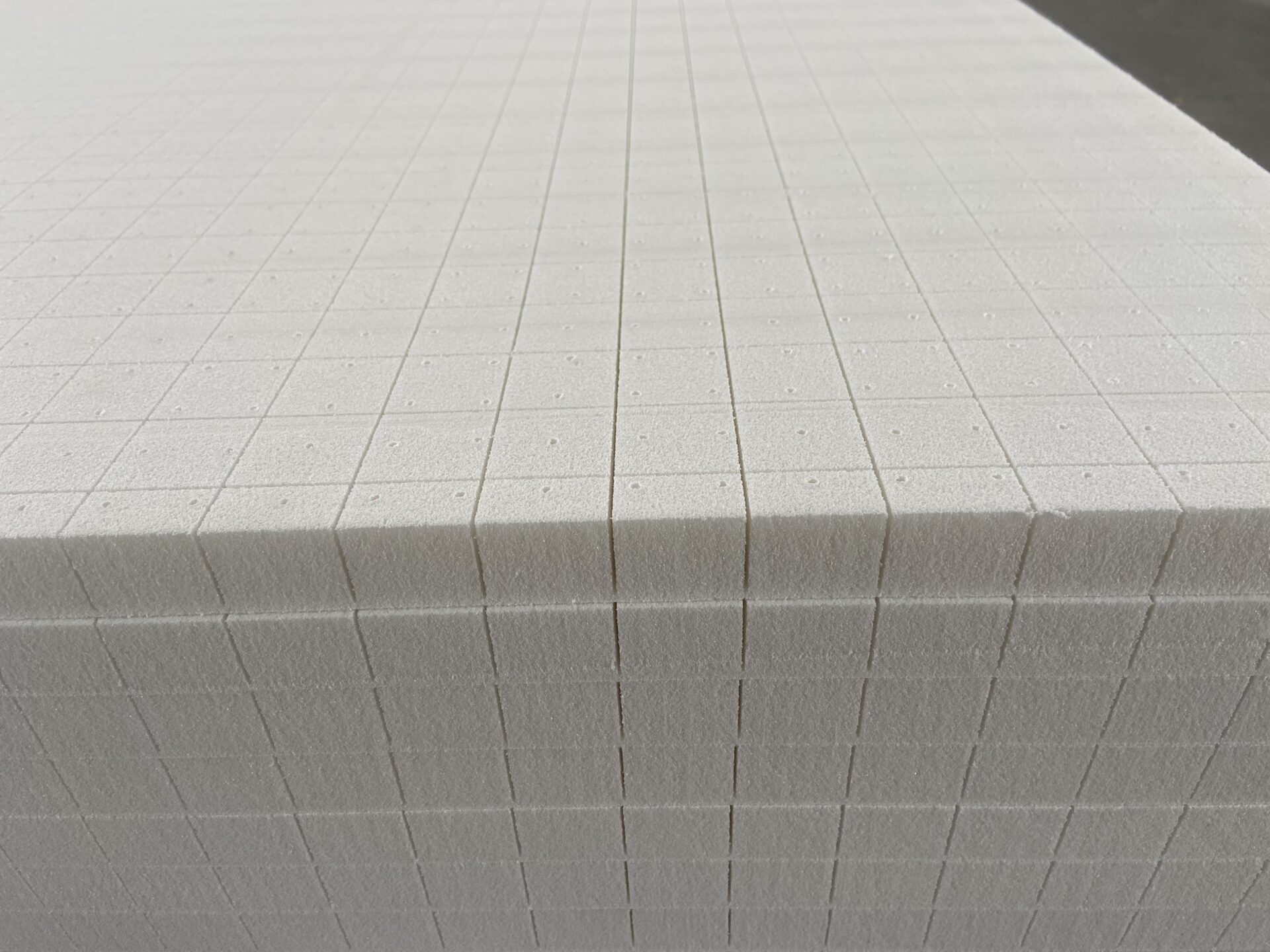

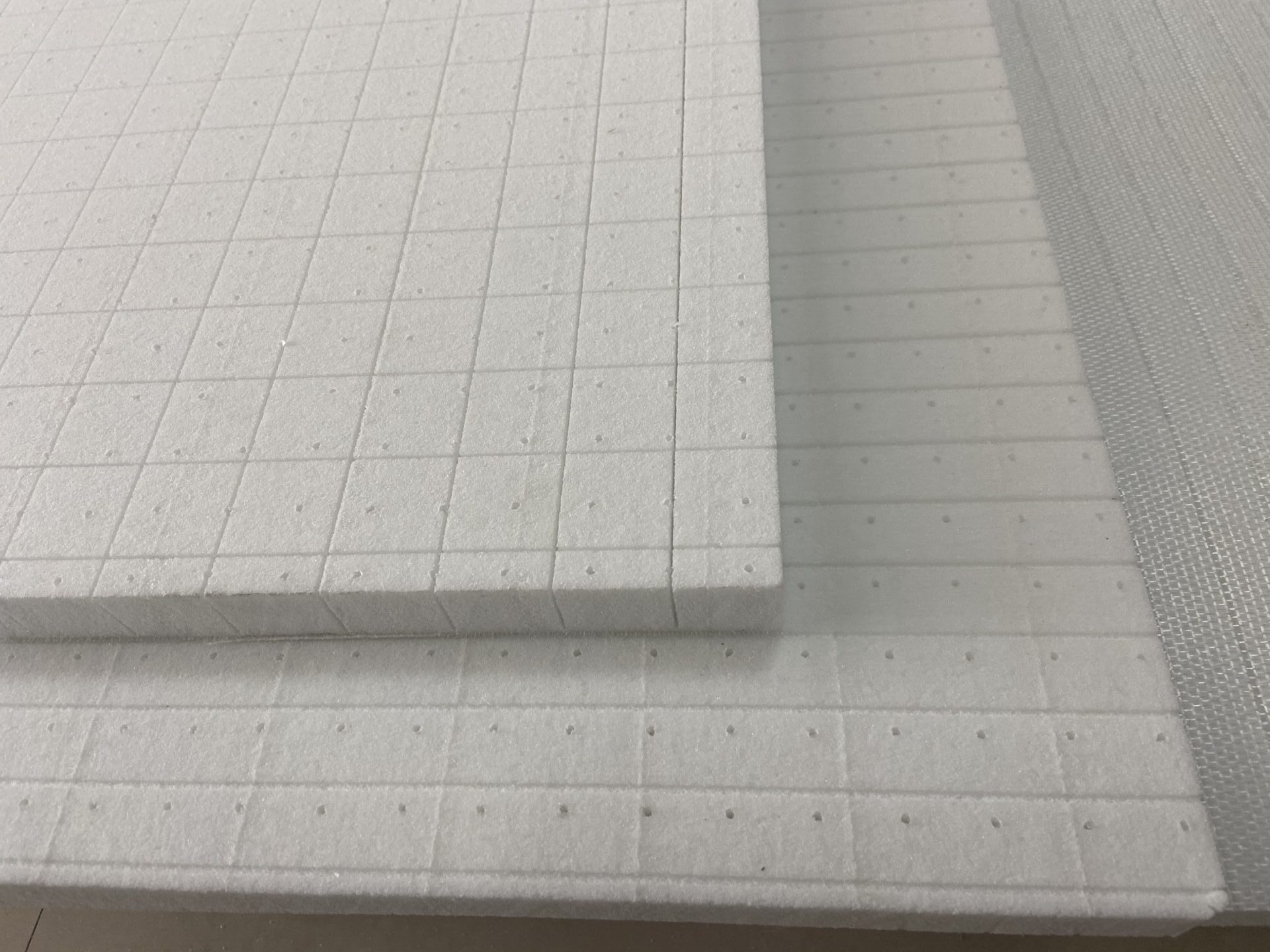

PET foam core material has good shear properties, so it is often used as a shear-resistant filler in shell structures. The cost of PET raw materials is lower than that of common core foam materials. PET is environmentally friendly.

PET can withstand a temperature of about 150°C for a short time during the processing. Its highest long-term working temperature is 100°C.

PET FOAM CORE MECHANICAL PROPERTIES

| PET 100 | PET 100HT | PET 150 | ||||||

| STANDARD | UNIT | MINIMUM VALUE |

AVERAGE VALUE | MINIMUM VALUE |

AVERAGE VALUE | MINIMUM VALUE |

AVERAGE VALUE | |

| DENSITY | IS0845 | kg/m³ | 100 | 110 | 105 | 110 | 140 | 150 |

| COMPRESSION STRENGTH | IS0844 | MPa | 1.2 | 1.4 | 1.2 | 1.4 | 2.0 | 2.5 |

| COMPRESSION MODULUS | DIN53421 | MPa | 65 | 80 | 65 | 80 | 110 | 130 |

| SHEAR STRENGTH | IS09122 | MPa | 0.7 | 0.75 | 0.7 | 0.75 | 1.1 | 1.3 |

| SHEAR MODULUS | IS09122 | MPa | 20 | 25 | 20 | 25 | 35 | 45 |

| ELONGATION AT Shear fracture | IS09122 | % | 4 | 8 | 4 | 8 | 4 | 8 |

| TENSILE STRENGTH | ASTM C 297 | MPa | 1.5 | 1.7 | 1.2 | 1.4 | 1.8 | 2.1 |

| TENSILE MODULUS | ASTM C 297 | MPa | 80 | 120 | 80 | 120 | 140 | 165 |

| HEAT CONDUCTIVITY AT ROOM TEMP | IS08301 | W/m.K | 0.033 | 0.033 | 0.036 | |||