Carbon fiber is the most essential component in today's composites industry.

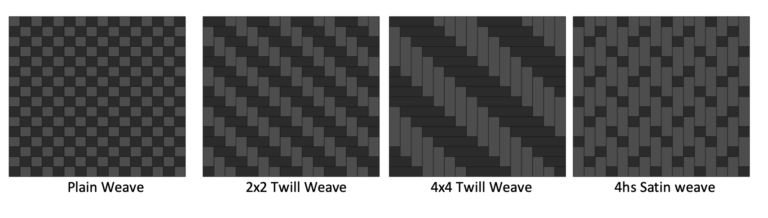

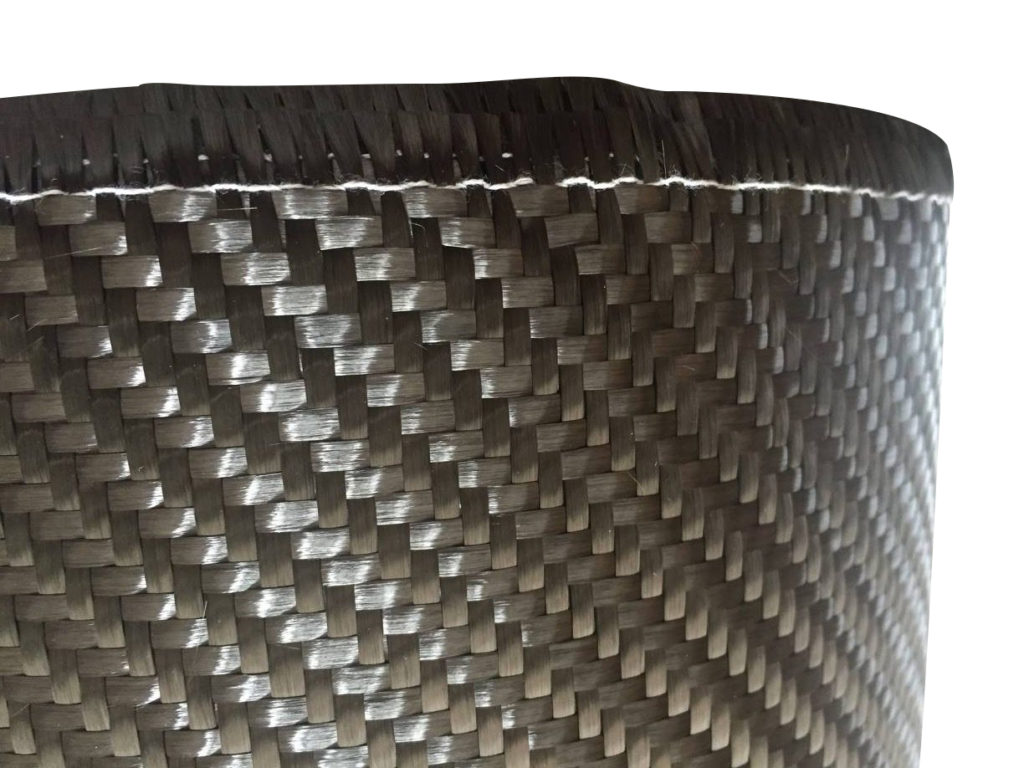

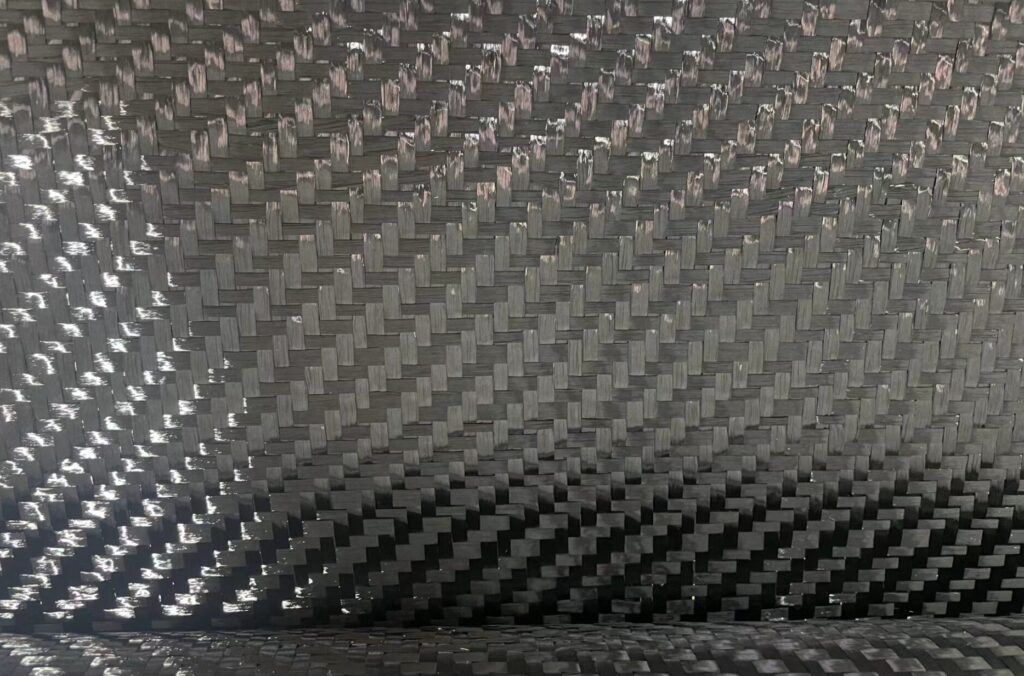

We supply carbon fiber fabrics woven in plain, twill and satin weaves and various weights.

Spec-List of Woven Carbon Fiber Fabric

| Weight | fiber type | weave | Fiber Count | Thickness | |

| (per 10mm) | |||||

| GSM g/m² | warp | weft | (in )mm | ||

| 100 | 1K | Plain | 7.5 | 7.5 | 0.14 |

| 120 | 1K | Plain | 9 | 9 | 0.16 |

| 120 | 1K | Twill | 9 | 9 | 0.16 |

| 140 | 1K | Plain | 10.5 | 10.5 | 0.17 |

| 140 | 1K | Twill | 10.5 | 10.5 | 0.17 |

| 160 | 1K | 8H Satin | 12 | 12 | 0.18 |

| 180 | 3K | Plain | 4.5 | 4.5 | 0.28 |

| 200 | 3K | Plain | 5 | 5 | 0.3 |

| 200 | 3K | Twill | 5 | 5 | 0.3 |

| 240 | 3K | Plain | 6 | 6 | 0.32 |

| 240 | 3K | Twill | 6 | 6 | 0.32 |

| 280 | 3K | Plain | 7 | 7 | 0.34 |

| 280 | 3K | Twill | 7 | 7 | 0.34 |

| 320 | 3K | 8H Satin | 8 | 8 | 0.36 |

| 320 | 6K | Plain | 4 | 4 | 0.38 |

| 320 | 6K | Twill | 4 | 4 | 0.38 |

| 400 | 6K | Plain | 5 | 5 | 0.42 |

| 400 | 6K | Twill | 5 | 5 | 0.42 |

| 400 | 12K | Plain | 2.5 | 2.5 | 0.46 |

| 480 | 12K | Plain | 3 | 3 | 0.52 |

| 480 | 12K | Twill | 3 | 3 | 0.52 |

| 640 | 12K | Twill | 4 | 4 | 0.64 |

Why use Carbon fiber?

| High strength and modulus |

| Low density; High strength-to-weight ratio |

| Good vibration dampning |

| Low creep rate |

| Low fatigue |

| Chemically inert, Non-Corrosive and highly resistant to alkalis and acids |

| Low thermal expansion and conductivity |

Major Applications of carbon fiber

| Sports equipment |

| Automobiles |

| Yachts/ship |

| Electronic gadgets |

| RC models |

| Aerospace |

| Medical equipment |

| Construction Reinforcement |

Why use CA Composites Carbon fiber fabrics?

-

We can custom manufacture these fabrics using toray, dowkasa, tairfyl, and Toho Tenax fibres based on your requirement and application.

-

All our carbon fiber cloths are compatible with a wide range of resin systems, including epoxy, phenolic, polyester, vinyl ester etc.

-

We can customise roll width to 1m, 1.27m and 1.5m

-

Roll length can be customized to 50m and 100m per roll

- To enhance the strength of composites, its common practice to use layers of materials like aramid, glass etc. You can source all these materials from us.

We also supply core materials like Nomex honeycomb, Kevlar Honeycomb, Epoxy Resin and Vacuum bagging materials.