CA Composites specializes in the construction of sandwich panels and similar structures.

Using autoclave, the largest structure we are able to produce is 8m long and 3m wide.

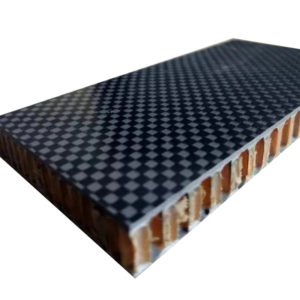

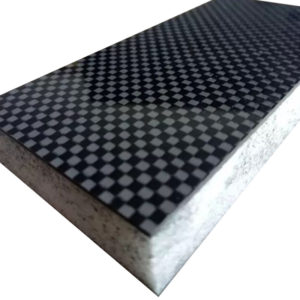

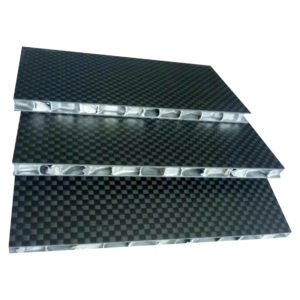

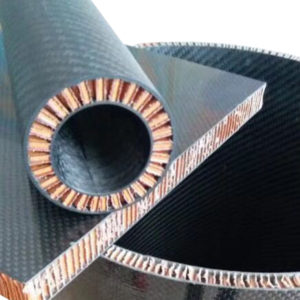

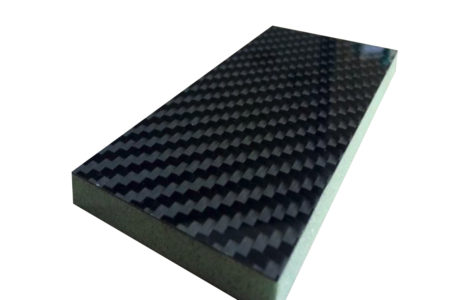

Sandwich panel is a special kind of structured composite in which one thin but stiff skin material is bonded to a lightweight but thick core. The core material is low strength material, but its higher thickness provides the sandwich composite with high bending stiffness with overall low density.

PVC foam core, Nomex Honeycomb Core, Kevlar Honeycomb Core, Aluminum Honeycomb core and balsa wood etc. are commonly used core materials.

Laminates of glass fiber, carbon fiber or combination of both are widely used as skin materials in these Sandwich panels.

The core material is bonded to the skins with a high-strength epoxy-based adhesive.

Applications of these Sandwich Structures

- building homes and furniture

- boat, hulls

- aircraft (interior and exterior parts)

- windmills

- automobile parts

- Communication equipment

- High-speed railways

These sandwich parts include flat panels as well as tubular and shaped structures and are all custom-made according to the client's requirements.