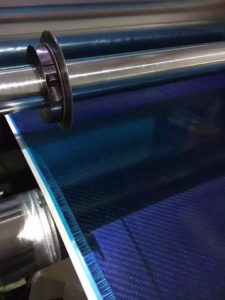

Prepreg is a widely used term for carbon/kevlar/glass fiber cloth impregnated with a controlled amount of Epoxy resin. CA Composites provides a wide range of prepregs made from Carbon fiber, Fiberglass, and Kevlar for aerospace and industrial applications.

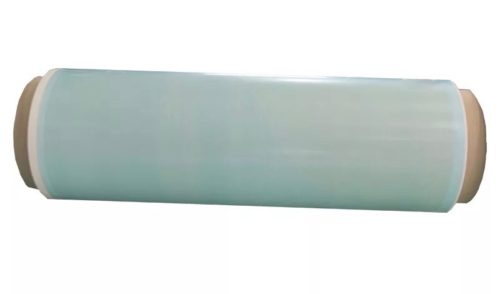

The prepregs are prevented from curing by storing in freezers. Ours can also be stored at room temperature for about 4-5 weeks. This is why our prepregs can be transported without freezer bags.

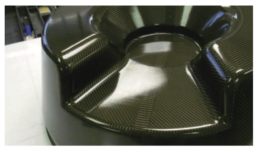

Prepregs need to be cured at very temperatures to obtain the required shape and strength. Our Prepregs can be cured at 90-150 degrees celsius.

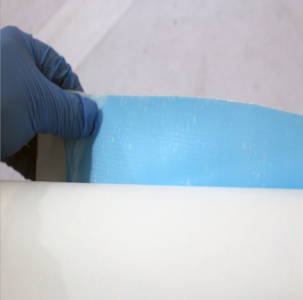

Unlike others, all our prepregs are protected with wax paper on one side and PE film on the other. This helps prevent dust and enhances the surface look of the cured parts.

| List of Resin systems used in prepregs supplied by CA Composites

|

|||

|

Resin Name |

Glass Transition (Tg) | Curing Condition | Remarks |

| TNYPH-23 | 100-110 | 120 minutes at 90 C + 120 minutes at 100 C | standard resin/slightly lower curing temp |

| TNYPH-42 | 120-130 | 30 minutes at 80 C + 100-120 minutes at 120-125C | standard tg/standard curing temp |

| JS-YPH170 | 175-180 | 30 minutes at 80 C + 90 minutes at 150 C | moderately high tg |

| TN-YPH170 | 170-190 | 30 minutes at 80 C + 45 minutes at 160 C | moderately high tg |

| JS-YPH200 | 195-205 | 30 minutes at 150 C + 120 minutes at 200 C (after cure) | highest Tg |

| TN-FR-Epoxy | 120-130 | 30 minutes at 80 C + 30 minutes at 150 C (or 90 minutes at 120 C) | Flame Retardant/ UL94 V-0 compliant |

| JS-FR-Epoxy | 120-130 | 30 minutes at 80 C + 90 minutes at 120 C | Flame Retardant/ UL94 V-0 compliant |

| JS-YPH150 | 140-150 | 5-10 minutes at 150 C | Superfast curing and moderately high tg |

Carbon Fiber Prepregs

High strength Carbon fiber yarn for UD Prepregs

Fiberglass Prepreg

Flame Retardant Epoxy Prepregs

Kevlar Prepreg

Prepreg Film Adhesive

S Glass Fiber Prepreg

Tooling Prepregs